The objective of the DEMONIAGAS project is to further develop and demonstrate the AMMONOX technology in pilot scale.

Lignocellulosic biomasses such us manure fibers and straw are not easily biodegradable and they need to be pretreated in order to be efficiently converted to methane in biogas plants.

The existing pretreatment methods increase significantly the cost of biogas production. A previous research project (AMMONOX) clearly documented in laboratory scale that ammonia is very effective for the pretreatment of manure fibers and other lignocellulosic biomasses. The objective of the DEMONIAGAS project is to further develop and demonstrate the AMMONOX technology in pilot scale.

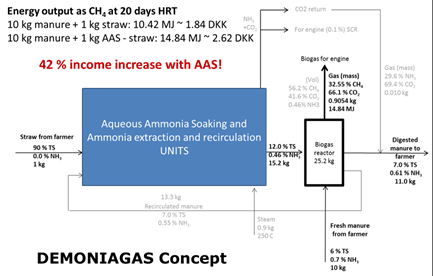

The project will demonstrate that the ammonia for pretreatment can be recirculated and that the technology requires no consumption of ammonia; on the contrary, it can produce a concentrate solution of ammonia that can be used as fertilizer.

Current biogas production in Denmark is partly based on mixing manure with other (additional) biomasses characterized by higher methane potential, such as slaughterhouse wastes, glycerin, energy crops, animal fat, fish oil, etc.

Addition of this type of biomasses increases the methane efficiency and thus the process profitability. However, due to the increased demand for biomass feedstock in the bioenergy sector and stricter regulations on the use of energy crops, the prices of these additional biomasses have increased significantly or their supply is becoming increasingly limited thus negatively affecting the overall economy of manure based biogas plants.

The alternative option is to use lignocellulosic biomasses such us manure fibers and agricultural or forest residues (such as straw), which however need to be pretreated in order to be efficiently converted to methane in biogas plants. To achieve high methane yield, the existing pretreatment methods are based on high temperature and pressure and/or use of harsh chemicals and increase thus significantly the cost of biogas production.

In a previous research project (AMMONOX), it has been clearly documented in laboratory scale that ammonia is very effective for the pretreatment of manure fibers and other lignocellulosic biomasses before anaerobic digestion. Specifically, aqueous ammonia soaking (AAS) at room temperature and pressure was able to increase the methane yield of manure fibers almost 200% and the methane yield of wheat straw almost 50% in less than 20 days digestion at 37°C.

The objective of the DEMONIAGAS project is to further develop and demonstrate the AMMONOX technology in pilot scale. The project activities include the designing, building and operation of a pilot plant. Thus, the possibility of efficient ammonia recovery from the stream after the AAS treatment and the reuse of ammonia for the AAS treatment of fresh biomass will be demonstrated. Additionally, it will be demonstrated that the AMMONOX technology requires no consumption of ammonia; on the contrary, it can produce a concentrate solution of ammonia that can be used as fertilizer.

One university (DTU), one biogas plant (Madsen Bioenergi), two engineering/consulting companies (Danish Gas Technology Center and EnviDan) and Lundsby Biogas A/S, who design and build biogas plants, are joining forces in order to successfully implement this project.