The gas analyser has a 4.2 m path length aluminium cell coated with nickel and the optic consists of a zinc selenide beam splitter. A spectrum is collected with an average of 10 scans at a resolution of 4 cm-1. The frequency range is from 750 to 5000 cm-1.

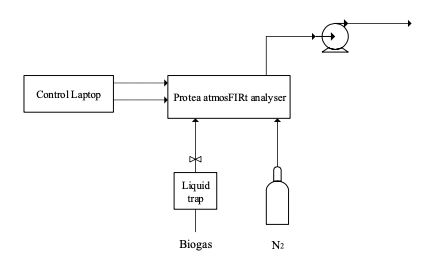

For biogas or combustion gas analysis the cell is heated to 60°C or 180°C for two hours to avoid water condensation on the cell-walls. Before sampling, dry N2 (99.99%) gas is purged into the cell with a gas flow rate of 3 L/min. Background scan of dry N2 is collected. Sample flow is 2.5 L/min and outlet gas is removed by the vacuum pump. The FTIR runs with the Protea Analyser Software (PAS), which allows for continuous data logging of e.g. concentration, pressure, and temperature. The setup is illustrated in figure 1.

The analyser is calibrated from the Protea Company for biogas components containing CH4, CO2, and H2S up to 70vol%, 50vol%, and 9840 ppm respectively. It is also calibrated for siloxane, ammonia, and water content. For combustion gas the analyser measure; CO, NO, NO2, N2O, SO2, NH3, HCl, HF, CH4, C2H6, C3H8, C2H4, HCHO, TOC, water, CO2, and O2. For fermentation gas the analyser can measure: CO2, ethanol, methanol, acetic acid, and water.

Figure 2 shows the experimental setup at Mølleåværket. At Mølleåværket the measured biogas was taken after the desulphurization process indicated with an A in the figure. For this process Mølleåværket is using a carbon filter. The capital letter B in the figure shows a manifold which can connect the Protea analyser (C) and other instruments. D (Figure 2) is the vacuum pump which removing the exhaust gas.